Originally posted 2/27/23

The last weekend in January we came up to the farm for a three day weekend in order to start tidying up some checklist items that need to be completed before things can move forward.

First was the need to finish emptying the steel building in preparation for spray foam insulation and the wood framing. This last bit of clean up had to be slower and more methodical, so as not to render the workshop unusable. After a little rearranging of outside storage areas, we were able to find at least a temporary home for everything.

A little more time was spent organizing tools in the workshop, along with removing the last set of old drawerless cabinets and a built-in sink, in order to free up some valuable floor space.

Even though it may be a while before I redesign the workshop into its final layout, it’s as close to functional as it needs to be to carry us through the rest of the build out for now.

I am continually impressed though, about the various relics we have recovered in the cleanup/ reorganization process. Quite a few unique items, with a bit of character, which will be of great use in the new design.

Saturday, while we were having lunch, my mom gave me an heirloom that my uncle had found while cleaning up his own house. Apparently, as boys, he and my father liked to get into various kinds of mischief, including rummaging around abandoned houses. On one such outing, they had found an old army bayonet with a broken tip. According to my uncle, my father had reground the tip, and made a leather sheath for it, complete with his initials stamped in.

I was surprised and touched to have a bit of my dad’s history come to life. It was also personally meaningful, considering my recent fascination with leathercraft.

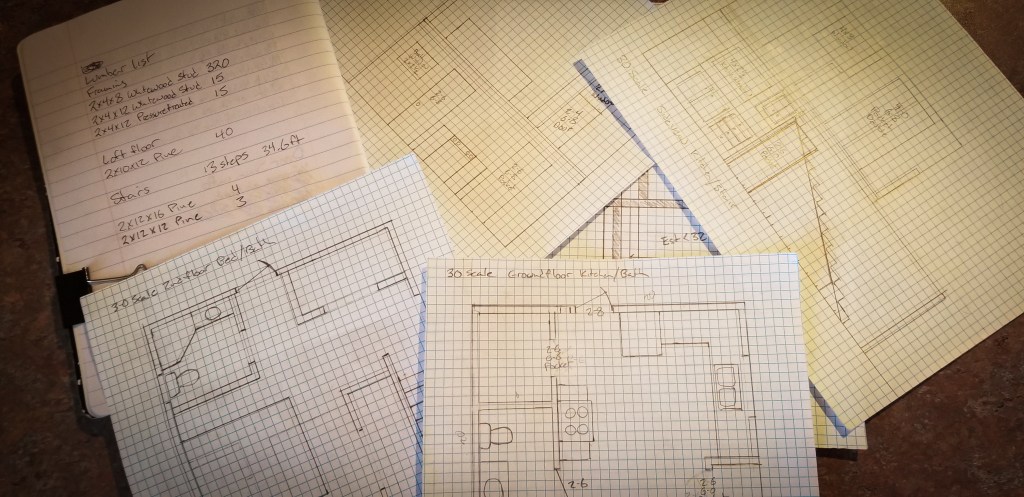

In the weeks leading up to our next working weekend, things seem to be picking up. Estimating and sourcing all the materials, planning the things that will be contracted out, and making sure everything happens in the correct timeline has turned into what feels like a full time job! This is a stark contrast from previous trips where we accomplished a lot with minimal planning, but it is reassuring as this is a sign that things are moving forward at a good pace.

Now it’s the end of February and we are back up for another three days and a long list of details to try and complete.

Friday we rolled in just in time to meet with an electrician for estimating the cost of dropping a new service line from the transformer. As much as both of us would like to be completely off grid, it’s simply not feasible yet.

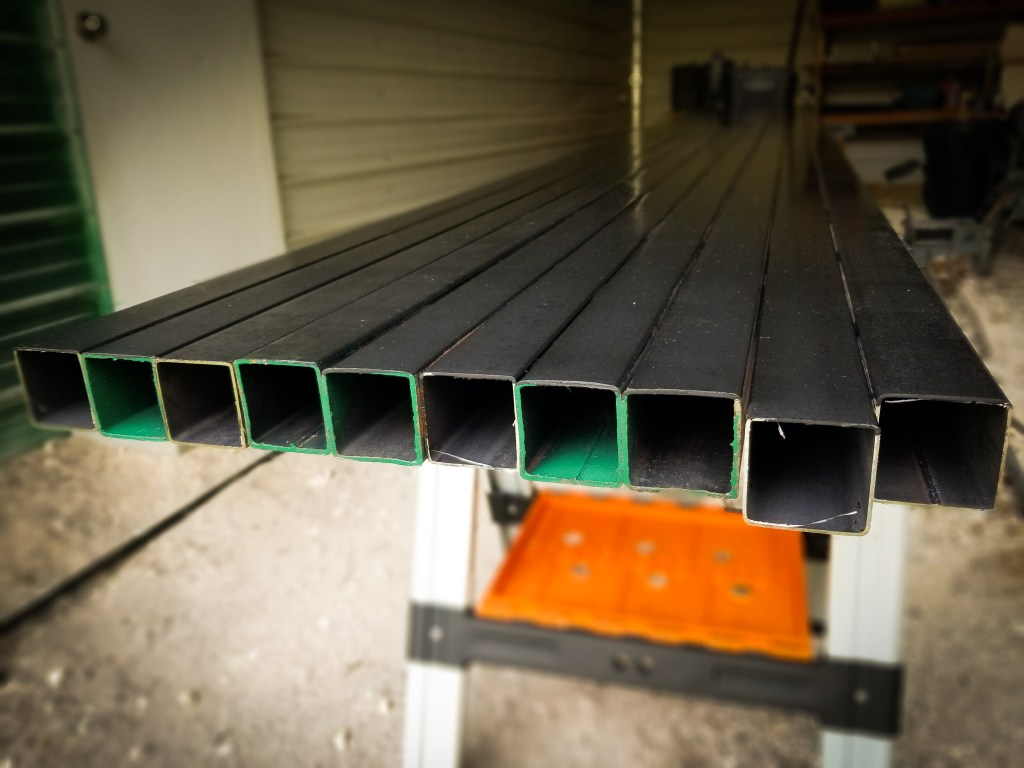

From there we hooked up the trailer and heading into town to retrieve some 2×2 16 ga. square tubing, similar to what the steel shell is framed with. This is what I will use to frame out the rough openings for the doors and windows we are adding.

We were fortunate enough to acquire three free doors to use in our build from my day job. They were going to be discarded at the last inventory and the Good Lord put me in the right place at the right time to take them home.

We had spent some time searching for windows, so that we could nail down our rough opening measurements. However we weren’t thrilled with the cost of new windows, and finding deals on used windows was not fruitful. I started researching how to build wooden windows and found the process well within my carpentry skill set, which immediately freed us from being constrained to buying first and then framing. Now we can just build out our desired rough openings and make custom windows to fit. As always, I am humbled by the gifts and talents that GOD has blessed me with, and hope to use them all for his glory.

So Saturday I set to work, carefully measuring, and doing the math for jambs and sills to figure up the dimensions for our door openings. Once I was satisfied it was back to cutting and welding in the pieces. Getting all the rough openings completed ended up taking most of the day, and I had hoped to get more accomplished than that, but I’ve learned to trust in the process, knowing everything will happen in it’s own time.

Sunday, I took on removing the existing electric conduit and fixtures, which will come in handy when it’s time to rewire the workshop.

It took a little while to get the upper level lighting down but everything happened very smoothly otherwise.

The final order of business for Sunday was to try and resurrect the old pressure washer that had been sitting idle for far too long.

With some fresh gas and a new spark plug, the old beast roared to life, and in no time we gave my wife’s Jeep a quick wash to make sure it was running well. This was a relief as it saves us a bit from not having to either rent or buy a new one!

With all that we come back in a few weeks to pressure wash, wrap the steel loft framing in stretch wrap to keep it from being fouled by foam insulation overspray, and layer the loft floor with plywood for the insulators to stand on. Then in short order, the building will be insulated and my father in law will be up for a weekend of carpentry. We are both very excited about the next steps and look forward to sharing the progress!

Thanks for reading, and God Bless!

One response to “Chapter 7 “Moving things forward…””

Wow! Get after it man! God bless you

LikeLike